|

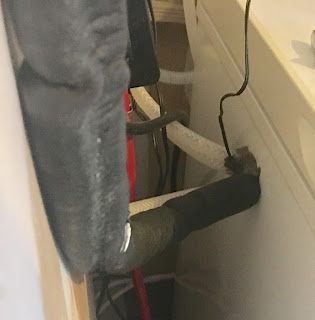

| This is the guts of the chiller, There is a compressor, evaporator, and coils where the refrigerant runs to cool the water below. |

The problem is that replacement would be rather expensive, > $1000. My carbonator still works and there are no other problems with the system.

I decided to DIY a chiller from a chest freezer.

I found a GE chest freezer on craigslist. 5.0 cubic feet. $75.

I picked it up and went to work.

I drilled two holes at the top of the left side to pass the lines.

I then placed the coils from the chiller inside the freezer.

Next I filled the freezer with 4 cases of bottled water to maintain the temperature.

I bought a temperature controller to turn the freezer into a refrigerator. The controller is set to keep the temp between 3 and 5 degrees Celsius. It converts the freezer to a refrigerator. If it were to freeze, the pipes would burst and I would have a flood on my hands.

Hooked it all up. Put the temp probe toward the bottom of the freezer to get the coldest reading. Put some putty to fill the holes.

Plugged it in and turned it on.

For under $100 I replaced my chiller with a much nicer looking, quieter, and more energy efficient solution.